OESH Shoes

Starting August 2021 until May 2022, I worked as an engineering apprentice full-time. Mostly working with machinery to manufacture 3D printers for shoe making.

In this experience, I spent hours learning and using heavy-duty machinery such as a Bridgeport CNC mill and waterjet. I also maintained and experimented with a bank of 12+ 3D printers to optimize and accelerate the manufacturing process. The two main products I worked on machining were the auger and heater block.

The auger was manufactured on a CNC bridgepoint mill with a rotary attachment. I use MasterCAM to generate a tool path. I learned how to use 3D adaptive features to manufacture the spiral shape of the auger using a ball end mill. I also built documentation for the

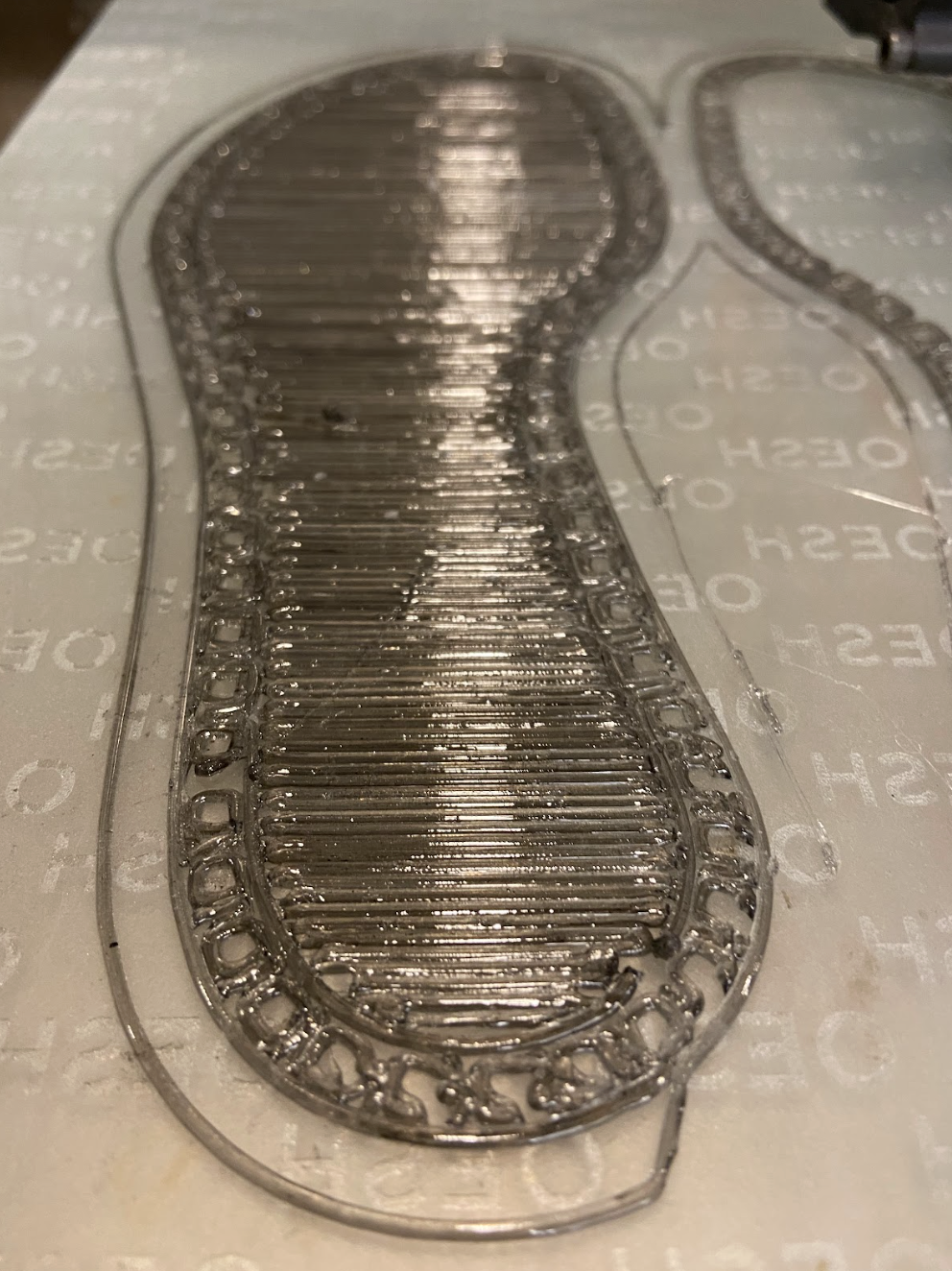

One of my projects working at OESH was running a series of experimental trials to test how changing different parameters would effect the quality of the part. Two of the main objectives to optimize are first layer quality and printing infill speed. The first layer of the shoe is the most important part, as it is what the customer sees most. Due to the confidentiality of this project, I cannot share the test results and visualizations for these trials. After about three months of trials, I found our most optimal parameter setting, which met all quality requirements and reduce total print time for one pair by 30%.

One of my projects working at OESH was running a series of experimental trials to test how changing different parameters would effect the quality of the part. Two of the main objectives to optimize are first layer quality and printing infill speed. The first layer of the shoe is the most important part as it is what is most viewed by the customer.